Precision in Practice: A Look into the Slion R&D Laboratory

At the core of Slion's R&D Center is our laboratory, a space equipped with 17 specialized instruments dedicated to evaluating every stage of production—from raw materials to finished components.

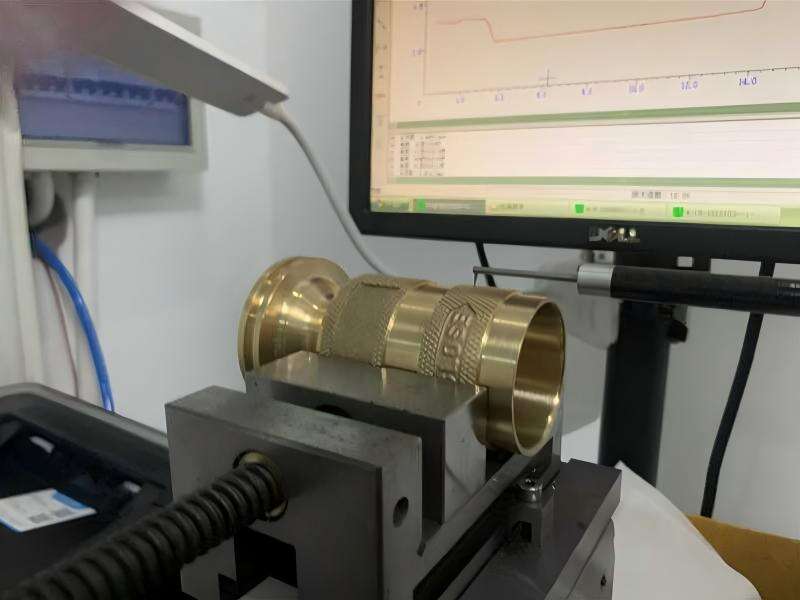

The image depicts one of our researchers conducting a precision measurement on a critical component: the Nozzle for a fire hydrant. This step is part of our rigorous quality control process, where dimensional accuracy is non-negotiable.

Our expertise lies in manufacturing products for high-pressure water systems. A significant part of our operations is dedicated to fire protection products, such as fire hydrant valves, check valves, and nozzles, which are exported to markets in North and South America. These critical products carry UL and FM certifications, affirming their compliance with the highest industry standards for safety and performance. Given their application, the precision of a Nozzle or the seal of a valve is paramount; any deviation could result in system failure under pressure.

Therefore, each batch undergoes systematic sampling and inspection. We verify the tolerances of every critical feature, ensuring that each fire protection product we deliver meets the exacting standards required for reliable performance in critical situations.

At Slion, the laboratory is not just a facility—it is the foundation of our commitment to functional reliability. Through measured and consistent verification, we ensure that our components, especially those as vital as a fire hydrant nozzle, perform as designed.